What Factors Cause Stress to your Pump System?

Education is a key element of our commitment to customers and engineers around the world. That’s why we provide in-depth articles about different phenomena in pumping and pump design. One area our readers always ask about is pump stress — specifically, what can cause stress to your pump system. Today, we focus on the two significant elements that should be taken into consideration when designing your system to prevent such stressors: vane pass and loading.

Vane pass

Vane pass refers to the pressure pulsations generated in a pump as impeller vanes pass the cutwater. Depending on how frequently the impeller rotates and the magnitude of the pressure pulsation, this phenomenon can affect the surrounding equipment. If the vane pass frequency is close to a natural frequency of some part in the pumping system, damage can occur. Here are a few ways engineers can reduce the impact of vane pass:

- Keep operating conditions within the optimal range.

- Avoid flowrates below 50% of the best efficiency point.

- Design the system such that all natural frequencies are out of the vane pass frequency range.

- Minimize the head-per-pump stage with the help of booster pumps.

- Avoid using three-vane impellers for high-head applications.

- Design supports to handle pressure pulsations from vane pass.

Load types

Pump systems also are subject to two main types of loads, the magnitude of which depends on operating conditions and layout. Hydraulic loads are internal, and include fluid pressure and internal momentum loads. Flange loads are external, including the weight and thermal expansion of the piping, misalignment, and axial loads.

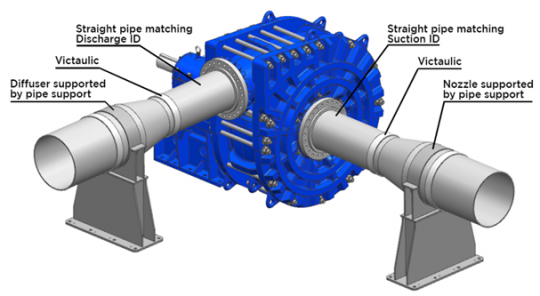

Operators should always identify and account for all loads in the system and install supports at key locations. If this is not done, the loads can damage the system. This is critical in multi-stage and high-pressure slurry pumps in series. To ensure loads are distributed properly, engineers should never use the pump itself as piping support. They can place supports near the pump, as well as at each coupling, to minimize the impact of loads. Engineers should always abide by GIW’s load standards!

It’s important to know what forces affect your pump system, and how to address problems when they arise. If your pump operation hits a snag or a part breaks down, just get in touch with us!

[cta] Do you have a pump-related question? Get in touch with us today to get an answer.[/cta]