5 Secrets to 125 Years of Success

Thomas Waterman Hagler Sr., President, March 11, 1947, to July 14, 1971. Photo by Fitz-Symms.

2016 marks the 125th anniversary of GIW Industries Inc. We’re amazed and humbled by this milestone because we know that it’s remarkably rare for a company to have such a long tenure.

Businesses rise and fall for many reasons, yet despite experiencing many of those reasons firsthand, GIW has continued to thrive. Our secret to success isn’t much of a secret: For the past century and a quarter, we at GIW have never lost sight of our customers.

We have always focused our energies, investments, and expansions on being the best pump partner for our clients. And although our company has a rich and colorful history, we’ve found five common values that have helped us stick to this commitment since GIW’s inception.

-

1884 map before Georgia Iron Works moved to 12th Street on the Augusta Canal.

Click to view larger.Hands-on problem-solving — GIW Industries began as a small foundry and machine shop in Augusta, Ga., in 1891. At that time, Georgia Iron Works was located along the Augusta Canal, which the company used to generate its electricity. When GIW began building slurry pumps in 1914, company employees dove headfirst into their clients’ most demanding applications, using whatever technology they had available to build the best equipment for their customers’ varied and complex environments. As the company has grown, this hands-on approach has taken employees around the globe to wherever mining, dredging, and industrial companies demand systems that expand the limits of moving slurry. The most valuable lessons and most innovative products continue to be developed through these down-and-dirty experiences.

-

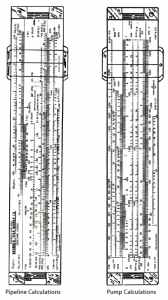

GIW Hydraulic Slide Rule conceived and designed by Danny Hagler and copyrighted in 1961. Photo from GIW Collection.

Click to view larger.Continual research and development — GIW employees focus on research and development not just to help clients realize success in any application but also to uncover knowledge that pushes the boundaries of the industry. Thanks to this focus, and to our highly regarded staff of slurry experts, we’ve built some of the most impressive products, facilities, and expertise in the industry. A great example of this is the GIW-developed hydraulic slide rule, which was created in the 1960s and now resides in the Smithsonian Institute. And in 1971, GIW led the way to become one of the first foundries in the U.S. to successfully convert to a 100% chemically bonded sand system. To accommodate growing interests in research and development, we expanded our facilities to include Thomson Machine and Fabricators in 1974, GIW Thomson Inc. in 1975, the pattern shop and urethane plant in 1976, and the GIW Hydraulic Testing Laboratory in 1976. GIW leaders also began supporting the continued education of our entire industry when, in 1977, we held our first “Transportation of Solids Using Centrifugal Pumps” course, which has become an annual event. To this day, research and development is still a cornerstone of what sets apart GIW from the competition.

-

In 1955, Alvin Postell helps move the second GASITE™ drop ball made. The drop ball, which was the largest casting at that time, was made for the quarry industry. Photo by Morgan Fitz.

Product creation driven by customer need — Over the years, many of our best products have been developed when clients came to us with their most challenging requests. In the late 1940s, a phosphate company received a directive from its home office to use slurry pumps constructed with components of “hard” or “white” iron, instead of the conventional gray iron, which was then the standard product. GIW engineers began experimenting with Ni-Hard, the patented product of the International Nickel Company. To obtain the Ni-Hard license, GIW had to meet certain qualifications in equipment and operation. Many early castings were scrapped, but eventually, GIW produced the Gasite® family of white irons. This registered trade name is recognized around the world, and it also serves as a great example of the lengths GIW employees will go to in order to solve a customer’s problem.

- Openness to company-wide change — What began as a family-run business is now an international brand name. This change didn’t happen overnight but was cultivated over decades of thoughtful leadership and a willingness to change. One of the greatest changes happened when KSB purchased 100% ownership of GIW in 1996. GIW continued to operate under the name GIW Industries until 2014, when its slurry products were officially rebranded as GIW® Minerals. Today, KSB and GIW offer single-source solutions for both water and slurry pump customers worldwide and, together, our companies offer over 125 years of experience in pumps and hydraulics!

-

The double-log ore and phosphate washer was designed by J. A. Hauser for use in the phosphate industry. Today, the original tracing of the design hangs in the engineering department of GIW Industries. Photo by Schaeffer Studio.

Click to view larger.Commitment to long-term customer relationships — In the early 1900s, GIW spare parts were manufactured for solids-handling pumps in the phosphate industry. The company’s first slurry client, IMC Fertilizer, is still a customer today under its current corporation, The Mosaic Company. Whether you’ve been our customer for 100 years like The Mosaic Company or just for one day, we’ll strive to make sure our slurry products make your business a success long into the future.

These are just a few of the examples throughout our history that have helped propel us to where we are today. We’re proud that investing in these principles has taken us from a local, family-run business to a global leader in the development and manufacture of slurry pumps. The evolution has spanned decades, and we’re grateful for every year and every experience that has contributed to our expanding slurry expertise.

Thank you for your ongoing support. We at GIW are looking forward to the next 125 years as we continue helping our customers realize success in their industries while staying ahead in our own!

[cta]GIW Trivia Time!To learn more about GIW history, click on “Answer” below each question below to see the answer.

Who was leading the company as President from 1891-1947 when GIW diversified its product line to include items like fire hydrants and manhole covers? [showhide type=”question1″ more_text=”Answer” less_text=”Close Answer”]With Henry Perkins as President, the company built a foundry, boiler house, blacksmith shop, and fabrication shop along 500 feet of 11th Street in Augusta, Ga. In addition to the usual listing of saw mill machinery and ornamental cast iron, by 1910, the product line included mining machinery, fire hydrants, and manhole covers.

[/showhide]

What year did the company come to be known as Georgia Iron Works Inc.? [showhide type=”question2″ more_text=”Answer” less_text=”Close Answer”]In 1892, stockholders voted to change the company’s name from The Perkins Manufacturing Co. to Georgia Iron Works Inc.[/showhide]

When did GIW convert from water power to electricity? [showhide type=”question3″ more_text=”Answer” less_text=”Close Answer”]In the 1950s, GIW converted to total electricity. Alvin Postell, who was with the company 38 years before he retired in 1986, recalled that when he was employed in 1948, the company mostly operated using water power from the Augusta Canal. In use since around the turn of the century, the waterwheel’s turbine turned a large beveled gear that was submerged in the canal. Through a series of shafts and gears, the turbine turned a continuous rope that extended from the top of the waterwheel tower to the top part of the machine shop, and there, with flat belts, it drove a series of pulleys and shafts that powered the machines. It was part of Postell’s job to splice the rope. When the water power from the canal was unavailable, the company would switch to electricity.[/showhide]

Who created and designed GIW’s now-famous Hydraulic Slide Rule? [showhide type=”question4″ more_text=”Answer” less_text=”Close Answer”]In 1960, Danforth W. Hagler, Tom Jr.’s brother, conceived and designed the GIW Hydraulic Slide Rule. Before its invention, each engineer in the engineering department had a large, thick notebook with about 100 pages of graphs. The slide rule incorporated many hydraulic pump and pipeline formulas. One side of the slide rule contained engineering formulas involved with performance of a pump, while the other side contained everything necessary for pipeline and production calculations. Even today, engineers still use the GIW Hydraulic Slide Rule for quick calculations of system performance.[/showhide]

In order to acquire the land that’s currently the location of GIW’s Grovetown facilities, what bizarre stipulation did the purchaser have to accept? [showhide type=”question5″ more_text=”Answer” less_text=”Close Answer”]When a site was found near Grovetown, Postell approached the owner, who was a widow. She was willing to sell 40 acres with an option for 60 more to Postell. There was, however, a peculiar stipulation: The widow, who sold pots and pans as side income, insisted that Postell also buy $350 worth of these utensils. Postell purchased the property and the pots and sold the land to GIW in 1964. He kept the pots.[/showhide][/cta] [cta]We have the experience, the capacity, and the rock-solid solutions necessary to meet your needs in every respect. If we can assist you in any way, please contact us at 1.888.TECHGIW (832-4449) or visit our website.[/cta]