What’s the Scoop on Stuffing Boxes?

If you’re like most operators, you have a slurry pump stuffing box to prevent fluid and material from leaking out of your system.

If you’re like most operators, you have a slurry pump stuffing box to prevent fluid and material from leaking out of your system.

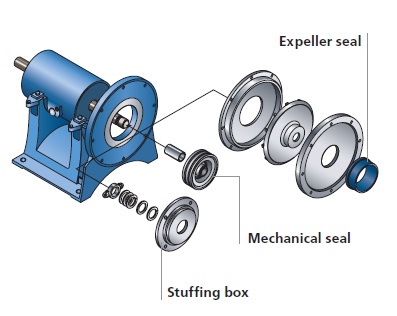

While this isn’t the only design available, a stuffing box is more economical and more forgiving than dynamic expeller and mechanical seal types. For these reasons, the stuffing box tends to be standard around the world.

However, despite their prevalence and ease of use, GIW Product Manager Richard Inglett points out that mechanics often install, use, or repair stuffing box shaft seals incorrectly.

“It’s easy, but it’s amazing how often it’s done wrong and mistreated,” Inglett says.

To avoid issues, Inglett recommends you follow a few tips for stuffing box success:

Choose the right product. At GIW, we have two standard types of LCC Stuffing Boxes available: the KE Low-Flow and the Throat Bushing. If you’re trying to minimize water usage — such as in hard-rock mining applications where the whole purpose is to de-water the slurry — then the KE is the simplest, most easily controlled type. It’s ideal in low-pressure, single-stage pumping. But when applications process a higher solids content, are more erratic with pressure spikes, or require two to three stages of pumps on the line, Throat Bushing or its SpiralTrac variation come in.[br][br]“Throat Bushing allows a little bit more water into the system — approximately twice as much as the KE — which reduces wear,” Inglett explains. “When the slurry gets heavier or when the operation’s [in] less stable operating conditions, I consider it a more rugged, consistent approach to shaft sealing.”

Choose the right product. At GIW, we have two standard types of LCC Stuffing Boxes available: the KE Low-Flow and the Throat Bushing. If you’re trying to minimize water usage — such as in hard-rock mining applications where the whole purpose is to de-water the slurry — then the KE is the simplest, most easily controlled type. It’s ideal in low-pressure, single-stage pumping. But when applications process a higher solids content, are more erratic with pressure spikes, or require two to three stages of pumps on the line, Throat Bushing or its SpiralTrac variation come in.[br][br]“Throat Bushing allows a little bit more water into the system — approximately twice as much as the KE — which reduces wear,” Inglett explains. “When the slurry gets heavier or when the operation’s [in] less stable operating conditions, I consider it a more rugged, consistent approach to shaft sealing.”- Pay attention to seal water requirements. The water supply to your stuffing box needs to be within the recommended range: If pressure is too low, slurry comes out the back of the stuffing box, causing premature wear of the components. If it’s too high, the packing can fail and possibly be expelled from the stuffing box.[br][br]“In typical process plant operations, we recommend 10 psig over operating pressure; however, for systems that are operating with greater variability, we recommend as much as 30 psig over discharge to handle those conditions,” Inglett says.[br][br] He also notes that water quality can play a role.[br][br] We also have found insufficient seal water and dirty supply water to be common issues. Both compromise shaft seal performance and the life of the components.[br][br] For the best results, seal water should be non-aggressive, have a neutral pH, and not contain solids greater than 2500 ppm and 50 microns maximum.

- [sidebar]Is a Stuffing Box My Only Option?

No! For customers who have very good control of their operations — no large pressure spikes, overly aggressive slurry, or extreme conditions — a waterless mechanical-type seal is an option. However, you must carefully maintain and operate slurry pumps with these seals as results can be catastrophic. If you have an issue with your stuffing box, severity tends to be gradual, giving you more time and flexibility to address issues.[/sidebar]Get a regulator. You need a different regulator based on the kind of stuffing box you have. For a KE box, a pressure-controlled regulator on the water going into your stuffing box is ideal. A flow-controlled water seal, on the other hand, can only be used on the Throat Bushing type, and it helps maintain the same flow regardless of the pressure. Both are readily available and easy to find. - Assemble and operate with care. From not lubricating the packing to over-tightening the gland or choosing the wrong packing material altogether, skipping a simple step can lead to poor sealing performance. If you correctly pack and maintain your stuffing box, you’ll have a pencil-sized stream of clear, temperate water coming from the back. If the water is too hot, you should loosen the fasteners to allow more flow. And if the water is cloudy, your flow needs more pressure.

“When it comes to stuffing boxes, you want everything properly selected, properly sized, and properly applied,” Inglett says.

If you have any questions along the way, give the professionals at GIW a call. As water is becoming more scarce and costly in many mining operations — and more necessary in others — we can help you find a solution in the LCC product line that fits your needs.

[cta] Do you have questions about the industry, our company, or our products and services? Please submit them to PWelty@giwindustries.com. To learn more about GIW, contact us at 1.888.TECHGIW (832-4449) or visit us online.[/cta]