Meet the Technology that Will Preserve Your Pumps

Copper mining involves working with some of thhe harshest materials in the world. As a result, mining companies must carefully monitor their slurry pumps for wear and schedule frequent shutdowns to replace worn parts. The cost of this maintenance goes far beyond just the price of parts; downtime and lost revenue can run into hundreds of thousands of dollars.

Copper mining involves working with some of thhe harshest materials in the world. As a result, mining companies must carefully monitor their slurry pumps for wear and schedule frequent shutdowns to replace worn parts. The cost of this maintenance goes far beyond just the price of parts; downtime and lost revenue can run into hundreds of thousands of dollars.

For one South American mine, the cost and frustration associated with its frequent shutdowns began to pose a major hurdle. To cut down on expenses and headaches, it turned to GIW Industries Inc. With our help and cutting-edge Enduraclad™ technology, the mine quadrupled its pump wear life, reducing downtime and boosting efficiency.

The trouble with tailings

The mine had struggled for years to reduce maintenance downtime in its tailings operations. Tailings — the material left over after the valuable metal has been extracted — consist of very fine particles that are highly abrasive in slurry. This material wears pumps out much faster than other equipment in the tailings line, increasing the frequency of downtime.

“They were having such severe wear that they were repairing these pumps every 400 to 450 hours,” Ronnie Willis, GIW Senior Product Manager of New Materials, says.

When considering replacement parts, manpower, and revenue lost due to downtime, the costs the copper mine was facing on a regular basis were staggering. It desperately needed a solution for more efficient operations.

An innovative solution

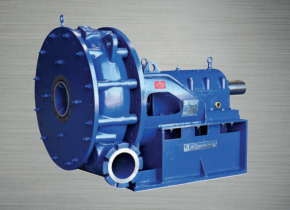

GIW offered the South American copper mine the answer it was looking for. An LSA centrifugal slurry pump was installed in a tailings booster application where GIW’s exclusive Enduraclad material was applied to the new suction liner.

“With the application of this new material, they’ve been able to extend wear life up to 2,000 hours and improve wear life of other related parts in the pump,” Willis explains.

This success comes from years of hard work and innovation from GIW’s team of hydraulic and metallurgical engineers, who are renowned as some of the best in the world. When Enduraclad made its debut in 2009, its uses were limited; it was applied only to suction liners and increased wear life up to three times. But since then, its capabilities have expanded to allow coating on other essential parts and provide even greater longevity for GIW pumps.

A worthwhile investment

As this copper mine will attest, although Enduraclad-bonded parts are more expensive, they are well worth the investment in harsh environments.

“It’ll cost more than an uncoated suction liner,” Willis says. “However, you are saving the cost of using fewer parts, the revenue loss during downtime, and the cost of maintenance. To remove and replace the parts on one of these pumps requires two to four people working with tools and lifting devices for 6 to 8 hours. So the longer you can keep the pump running with nobody touching it, the more operational cost you save.”

Economy is something GIW values and strives to pass along to its customers.

“We’re not just developing these really specialized materials and processes and charging higher prices,” Willis adds. “We’re also continually looking for ways to reduce the cost of materials so we have a product that serves customers’ needs and fits their budgets.”

GIW constantly looks at new materials and processes that can improve pump wear life for customers like the South American copper mine. GIW metallurgical experts are already testing new cladding materials that will last even longer than the current ones, and there may be even greater improvements in the future with enhanced Enduraclad material.

“GIW is constantly looking for solutions that add value to our products,” Willis says. “This is one of the ways GIW meets our customer expectations for continuous improvement.”

[cta]Is your pump’s short wear life bleeding you dry? Let GIW show you how we can enhance even the most abrasive slurry processes and extend time between shutdowns. To learn more about how GIW products can reduce production expenses for your company, contact us at 1.888.TECHGIW (832-4449) or visit giwindustries.com.[/cta]